Corrosion of accelerator cables can cause significant problems in vehicles, including impaired performance, increased safety risks, and costly repairs. To prevent accelerator cable corrosion, it is essential to understand the causes and implement effective preventive measures. This article will explore the causes of accelerator cable corrosion and provide detailed preventive measures to keep your cables in optimal condition.

Understanding Corrosion

Corrosion is a natural process that occurs when metals react with environmental elements such as oxygen, moisture, and chemicals. This reaction leads to the deterioration of the metal, forming rust and other corrosive compounds. Accelerator cables, typically made of steel or other metal alloys, are particularly susceptible to corrosion due to their exposure to harsh conditions under the hood of vehicles.

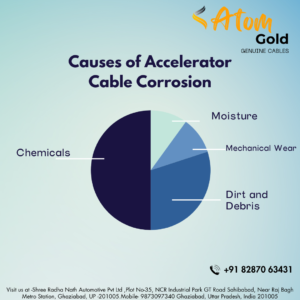

Causes of Accelerator Cable Corrosion

- Moisture: Water from rain, road spray, and humidity can penetrate the protective coverings of cables, leading to rust formation.

- Chemicals: Road salts, used for de-icing, and other chemicals can accelerate the corrosion process.

- Dirt and Debris: Accumulation of dirt and debris can trap moisture and chemicals against the cable, promoting corrosion.

- Mechanical Wear: Regular use and friction can wear away protective coatings, exposing the metal to corrosive elements.

Preventive Measures

Regular Inspection and Maintenance:

- Routine Inspections: Regularly inspect accelerator cables for signs of wear, rust, or damage. Early detection can prevent further deterioration.

- Cleaning: Keep cables clean by removing dirt, grime, and road salt. Use a gentle brush and a mild detergent to clean the cables, followed by thorough rinsing and drying.

Proper Lubrication:

- Lubricant Selection: Use high-quality lubricants specifically designed for automotive cables. Avoid water-based or low-quality lubricants that can wash away or evaporate quickly.

- Application: Apply lubricant to the entire length of the cable, ensuring it penetrates into the cable housing. Reapply lubrication at regular intervals or as recommended by the vehicle manufacturer.

Protective Coatings and Covers:

- Protective Coatings: Apply anti-corrosion coatings or sprays to the cables. These products form a barrier against moisture and chemicals, preventing corrosion.

- Cable Covers: Use protective covers or sleeves to shield cables from environmental elements. These covers can be made of rubber, plastic, or other durable materials.

Environmental Control:

- Garage Storage: Whenever possible, store vehicles in a garage or covered area to protect them from direct exposure to rain, snow, and road salt.

- Weatherproofing: Ensure that engine compartments and cable housings are properly sealed to prevent water ingress. Check for any gaps or openings that may allow moisture to reach the cables.

Material Selection:

- Stainless Steel Cables: Consider using stainless steel cables, which are more resistant to corrosion than standard steel cables. Although they may be more expensive, their durability can offset the initial cost.

- Coated Cables: Opt for cables with protective coatings, such as zinc or Teflon, which provide an additional layer of defense against corrosion.

Addressing Corrosion Immediately:

- Early Treatment: If you notice any signs of corrosion, address them immediately. Clean the affected area and apply a rust converter to neutralize the corrosion.

- Replacement: In cases of severe corrosion, replace the accelerator cable to ensure the safety and performance of the vehicle.

Professional Maintenance:

- Regular Servicing: Have your vehicle regularly serviced by a professional mechanic who can inspect and maintain accelerator cables and other components.

- Specialized Services: Consider specialized anti-corrosion treatments offered by automotive service centers, such as undercoating or rust-proofing sprays.

Practical Tips for Vehicle Owners

Seasonal Maintenance:

- Winter Care: During winter, be extra vigilant about cleaning and lubricating cables, as road salt and moisture are more prevalent.

- Summer Care: In hot and humid climates, inspect cables more frequently to prevent moisture buildup.

DIY Maintenance:

- Tool Kit: Keep a basic tool kit and maintenance supplies in your vehicle for on-the-go inspections and minor repairs.

- Manual Reference: Refer to the vehicle’s owner manual for specific guidelines on cable maintenance and lubrication.

Awareness and Education:

- Stay Informed: Keep up-to-date with the latest maintenance techniques and products available for preventing corrosion.

- Join Forums: Participate in automotive forums and communities to share experiences and learn from other vehicle owners.

Conclusion

Preventing accelerator cable corrosion is crucial for maintaining the safety, performance, and longevity of your vehicle. By understanding the causes of corrosion and implementing regular maintenance practices, you can protect your accelerator cables from the damaging effects of rust and corrosion. Regular inspections, proper lubrication, the use of protective coatings and covers, and professional maintenance are key strategies to keep your cables in excellent condition. With these preventive measures, you can ensure that your vehicle’s accelerator cables remain reliable and corrosion-free for years to come.

Taking the time to care for your vehicle’s accelerator cables not only enhances the vehicle’s performance but also provides peace of mind knowing that you are proactively preventing potential issues. Stay diligent, informed, and proactive in your maintenance efforts, and your accelerator cables will reward you with dependable and smooth operation.

Find the Atom Gold difference today – where the heritage of the past is merged with the technology of the future, and quality is the standard.

For more information about our products or to place an order, visit our website or contact us at our office in Ghaziabad, UP. Let us help you drive with confidence, powered by the best accelerator cables in the industry.

Visit us at -Shree Radha Nath Automotive Pvt Ltd , Plot No-35, NCR Industrial Park GT Road Sahibabad, Near Raj Bagh Metro Station, Ghaziabad, UP -201005. Mobile- 9873097340, 82870 63431 Ghaziabad, Uttar Pradesh, India 201005